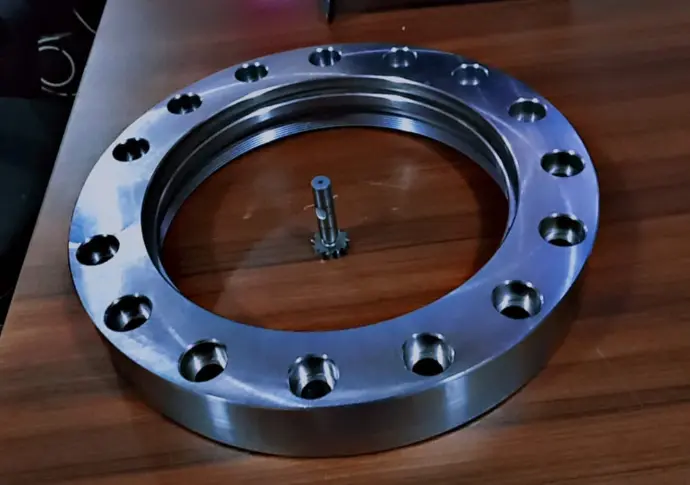

Unveiling our newest products

We do it all, Design, Provide the Material, Machine the part, and weld it in place if necessary!

Have a look at some of our Highlights

A Friendly and Developing Machine-shop. We’re constantly looking to propose new products and better Quality.

At NICO, you can expect Good quality, We stand behind our Products.

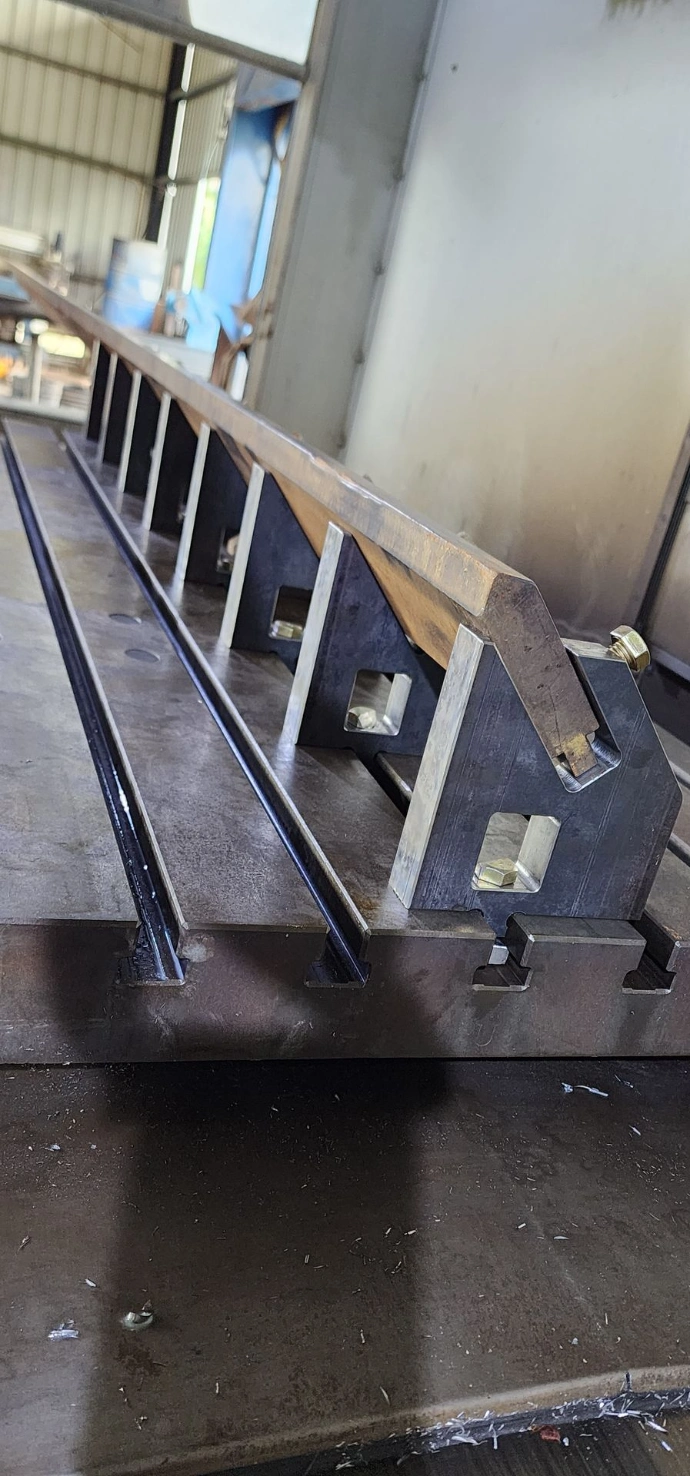

Making purple Chips is what we do best

Where ideas come to life

From start to finish we do it all

Convert material into Parts

CNC Machining

Precision milling and turning for metal and plastic parts. Prototypes and production.

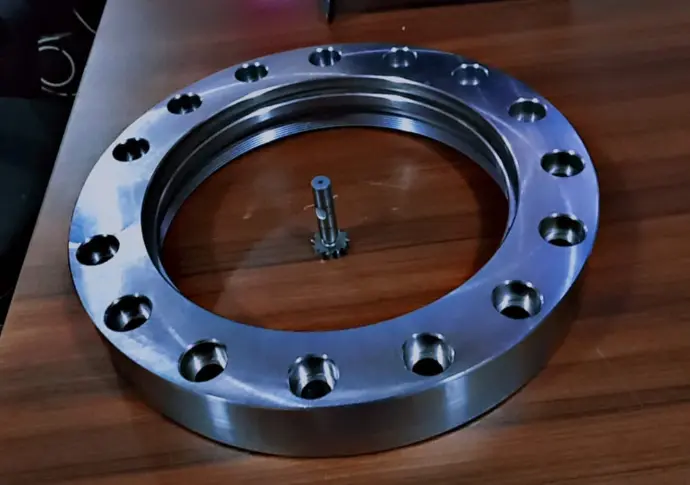

Sheet Metal Fabrication

CNC Plasma cutting is an efficient way of getting nearly any 2D design shape out of a flat sheet. With our 200 Amp Hypertherm Machine we can cut from .03 inch thick all the way up to 3 inches

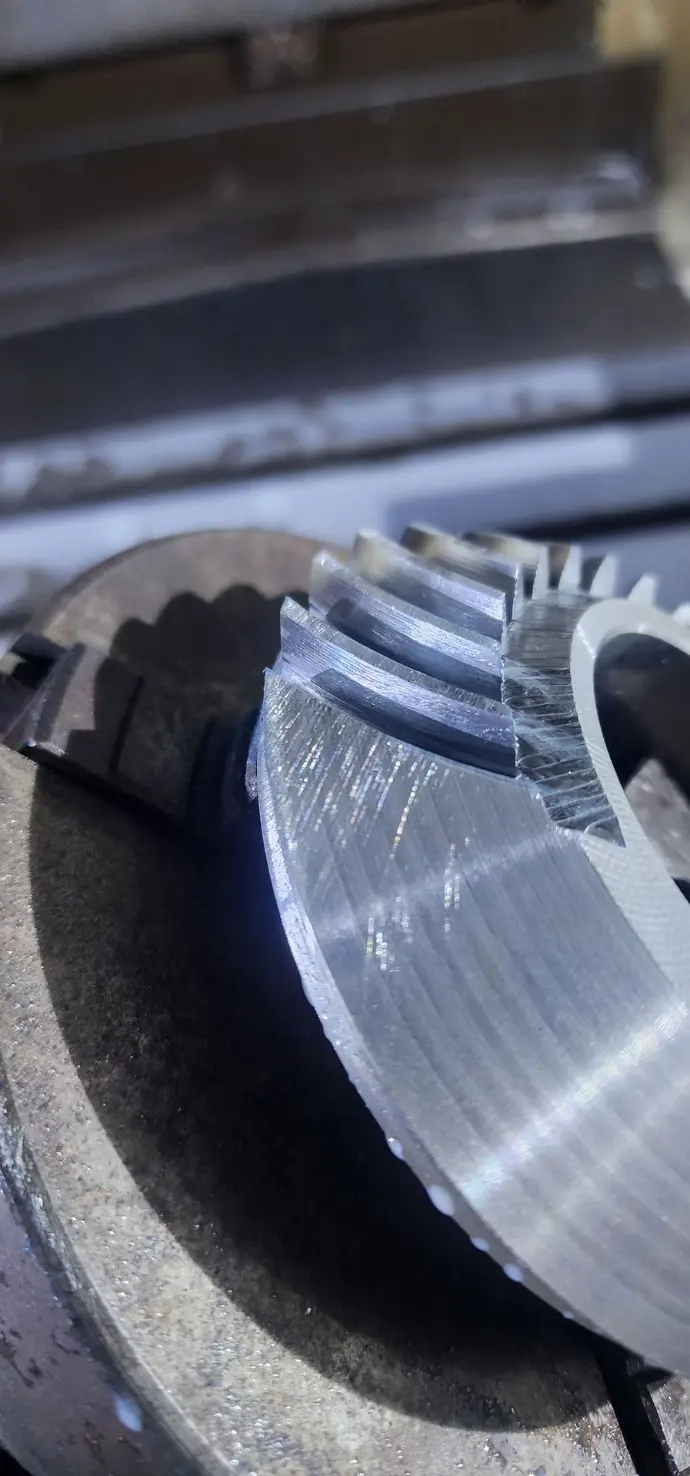

Restoration of worn parts

In some cases, you may not want to buy new parts, so we also offer restoring your damaged or worn parts.

CNC Machining

- CNC milling machines are capable of precision so try to use this to your advantage

You name it we do it

As a starting business in a small country, we need to have the ability to do more than Machining and drinking coffee. And that's why we do it all. Design, Provide the material, Cut the material, Drill holes, Thread holes, and Weld it together. Most importantly, yes we do painting.

Advantages of CNC Milling

CNC milling has a number of advantages over other manufacturing processes.

- Can produce quality parts of almost any shape or form

- Cost-effective machining for prototyping and short runs

- High dimensional tolerances are possible

- Smooth finishes can be achieved

- Can produce identical parts repeatedly

- Milling machines can operate at high speeds, producing parts quickly.

- A single machine can produce a wide variety of part shapes and sizes

- Milling can be applied to many materials, including metals, plastics, and composites.

- CNC machines can be programmed using computer-aided design (CAD) software, which makes it easy to create and change designs.

Design Consideration for Milling

When designing parts to be CNC milled, there are several tips to keep in mind:

- CNC milling machines are capable of precision so try to use this to your advantage

- Avoid deep pockets which are difficult to machine

- Sharp inside corners are often difficult so consider using a radius

- Apply chamfers to top edges to reduce sharpness and improve appearance.

- Thin walls and other flimsy shapes can be difficult to machine as they may not hold up against the pressure of the cutting action.

- Try to create shapes that do not have complex curves in more than one axis – as it may be difficult to hold during machining.